Customized plastic profiles for electronics are a key component in the design of high-performance devices. Thanks to advanced plastic extrusion technology, Mavis produces tailor-made plastic profiles, ensuring tight tolerances, specific materials, and integrated functionalities. Accuracy and customization are essential to meet the needs of designers and manufacturers operating in advanced technological sectors.

Applications of custom electronic profiles

Plastic profiles for electronics are used in multiple applications, including:

- Protective gaskets for electrical panels and electronic devices to prevent dust and moisture infiltration.

- Cable ducts and guides in rack cabinets and control systems for organized and safe routing.

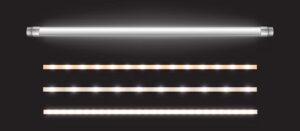

- LED profiles such as diffusers in polycarbonate or PMMA for technical lighting.

- Heat-dissipating profiles made from engineering polymers to manage heat generated by LED lamps.

- Electrical insulation and safety coverings for metal parts and sharp edges.

Technical features of plastic profiles for electronics

The custom plastic profiles for electronics produced through extrusion are designed to achieve an optimal combination of technical properties:

| Feature | Description |

|---|---|

| Electrical insulation | Dielectric materials such as PVC, ABS, TPE, and PP prevent short circuits and current leakage. |

| Dimensional precision | Tight tolerances ensure precise housing and guiding systems. |

| Thermal and mechanical resistance | High-performance materials withstand operational stress and temperature variations. |

| Flame retardancy | Compliant with UL94 V0 standards for fire safety. |

| Environmental protection | Excellent resistance to chemical and atmospheric agents ensures long-term durability. |

| Heat dissipation | Use of dissipative materials for LED profiles. |

| Light transparency and diffusion | Polycarbonate and PMMA are ideal for diffusers and LED components. |

Advantages of extruded plastic profiles for electronics

- Geometric versatility: complex cross-sections and customized lengths.

- Production efficiency: continuous and scalable manufacturing.

- Functional integration: possibility to include channels for fasteners or reinforcements.

- Lightweight design: reduced weight without compromising strength.

- Enhanced safety: flame-retardant and stress-resistant materials.

- Durability: resistant to water, dust, and aggressive agents.

- Easy processing: cutting, drilling, and assembly operations are simplified.

FAQ on custom electronic plastic profiles

1. Which plastic materials are most commonly used for extruded profiles in electronics?

PVC, ABS, TPE, polypropylene, polycarbonate, and PMMA are selected based on flexibility, insulation, transparency, or dissipative properties.

2. What is extrusion and why is it important for customized profiles?

Extrusion is a continuous forming process that allows complex geometries and infinite lengths, ensuring high levels of customization and precision.

3. How does Mavis ensure the quality and safety of its plastic profiles?

We use UL94 V0 certified materials compliant with RoHS and REACH regulations. Each profile undergoes mechanical, thermal, and dimensional testing to ensure top-level reliability.

Request your custom electronic profiles

Mavis provides dedicated technical consulting and customized quotes for plastic profiles for electronics made with top-quality materials and advanced extrusion technology. We work alongside designers and manufacturers to develop tailor-made solutions that meet dimensional, functional, and regulatory requirements of the electronics industry.

For advice or information, request a free quote for plastic profiles and seals by filling out the form below.